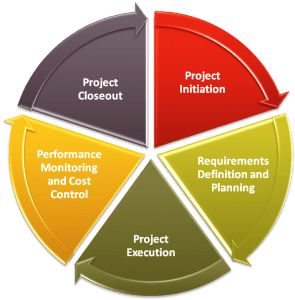

Project Management Office (PMO) focuses on 0realizing the defined project within the agreed quality, time, and cost requirements. Managing the internal and external resources in an efficient way to best suit the interests of the customers is one of most important goals of our PMO.

Through our PMP (Project Management Professional) certified engineers we are able to supply customers with complete turnkey automation projects.

Project Management Office (PMO) focuses on 0realizing the defined project within the agreed quality, time, and cost requirements. Managing the internal and external resources in an efficient way to best suit the interests of the customers is one of most important goals of our PMO.

Through our PMP (Project Management Professional) certified engineers we are able to supply customers with complete turnkey automation projects.

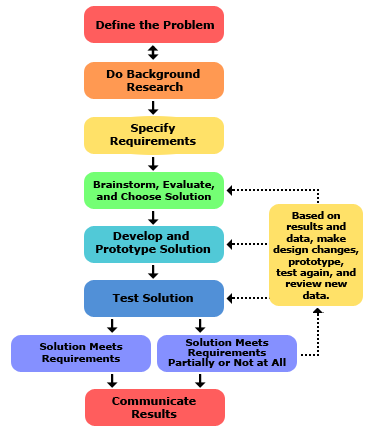

Thrust Automation provides complete design and planning services in the field of industrial automation in accordance with international standards. Our licensed engineers are trained to use latest technology, modern software tools and reliable equipment and solutions.

we take full responsibility for defining the targets, discovering the options and making an informed system decision in order to provide complete customer satisfaction.

Services

- Site survey.

- Design study.

- Project schedule.

- Functional specification for the control system.

- Control strategy and operational concept.

- List if IOs and components.

- Selection of devices and components.

- Cabinet design and assembly.

- Programming of controller.

- Design and configuration of the HMI/SCADA system.

- Network and communication protocol configuration.

- Documentation.

- Factory Acceptance Test (FAT).

Thrust Automation provides complete design and planning services in the field of industrial automation in accordance with international standards. Our licensed engineers are trained to use latest technology, modern software tools and reliable equipment and solutions.

we take full responsibility for defining the targets, discovering the options and making an informed system decision in order to provide complete customer satisfaction.

Services

- Site survey.

- Design study.

- Project schedule.

- Functional specification for the control system.

- Control strategy and operational concept.

- List if IOs and components.

- Selection of devices and components.

- Cabinet design and assembly.

- Programming of controller.

- Design and configuration of the HMI/SCADA system.

- Network and communication protocol configuration.

- Documentation.

- Factory Acceptance Test (FAT).

Thrust Automation offers a full suite of electrical engineering capabilities to manage projects from conceptual design and specification through to detailed design for installation and finally installation testing, certification and inspection.

- MV and LV power supply and distribution systems, with or without multiple points of supply, RMU’s, and off-grid systems

- Distribution and motor control centers (MCCs), including pre-built and pre-tested transportable options

- Motor control systems, including variable speed drives, soft starters and their associated metering and protection equipment

- Harmonic mitigation and elimination systems for plants with large percentages of VSD and switch-mode power supply loading, such as data centers Management

Thrust Automation offers a full suite of electrical engineering capabilities to manage projects from conceptual design and specification through to detailed design for installation and finally installation testing, certification and inspection.

- MV and LV power supply and distribution systems, with or without multiple points of supply, RMU’s, and off-grid systems

- Distribution and motor control centers (MCCs), including pre-built and pre-tested transportable options

- Motor control systems, including variable speed drives, soft starters and their associated metering and protection equipment

- Harmonic mitigation and elimination systems for plants with large percentages of VSD and switch-mode power supply loading, such as data centers Management

ESD (Emergency Shutdown) & F&G (Fire & Gas) systems protect against the possibility of a process excursion on topsides process plant developing into an incident (e.g. loss of containment), and to respond to emergency situations detected by other safeguarding facilities requirements for programming the PLC. Our area of specialization is Allen Bradley, SIEMENS, HIMA, GE and MODICON and other types of processors can be accommodated.

Our supplied F&G and ESD systems can have the following features and certifications based on client’s specification:

- Redundancy for CPU and IO on various levels

- Line monitoring and system diagnostic

- Safety Integrity Level (SIL2/SIL3) certification

- EExn certification for hazardous area

ESD (Emergency Shutdown) & F&G (Fire & Gas) systems protect against the possibility of a process excursion on topsides process plant developing into an incident (e.g. loss of containment), and to respond to emergency situations detected by other safeguarding facilities requirements for programming the PLC. Our area of specialization is Allen Bradley, SIEMENS, HIMA, GE and MODICON and other types of processors can be accommodated.

Our supplied F&G and ESD systems can have the following features and certifications based on client’s specification:

- Redundancy for CPU and IO on various levels

- Line monitoring and system diagnostic

- Safety Integrity Level (SIL2/SIL3) certification

- EExn certification for hazardous area

HMI is the interface between the equipment and the operator. There are lots of devices used for this purpose, touch screens, pushbutton panels, and graphics screens, and in some cases PC’s.

Thrust Automation has an extensive knowledge and experience in developing user operator interfaces. We listen to the operators and get them involved in defining the fine points of operator’s control environment. Effective control interface leads to higher product quality and increased production.

HMI is the interface between the equipment and the operator. There are lots of devices used for this purpose, touch screens, pushbutton panels, and graphics screens, and in some cases PC’s.

Thrust Automation has an extensive knowledge and experience in developing user operator interfaces. We listen to the operators and get them involved in defining the fine points of operator’s control environment. Effective control interface leads to higher product quality and increased production.

PLC Systems are capable of handling the most demanding of process control programming and control tasks. Whether counting parts as they leave a process, to controlling all of the discrete steps in the manufacturing process, PLC Systems can provide a solution.

The programming of Programmable Logic Controllers is a routine task for us based upon the description of the client’s requirements for programming the PLC. Our area of specialization is Allen Bradley, SIEMENS and MODICON, but other types of processors can be accommodated.

PLC Systems are capable of handling the most demanding of process control programming and control tasks. Whether counting parts as they leave a process, to controlling all of the discrete steps in the manufacturing process, PLC Systems can provide a solution.

The programming of Programmable Logic Controllers is a routine task for us based upon the description of the client’s requirements for programming the PLC. Our area of specialization is Allen Bradley, SIEMENS and MODICON, but other types of processors can be accommodated.

Our SCADA systems are configured to the customers’ requirements by our own staff and range from simple Human-Machine Interfaces to complete monitoring and control systems.

Supervisory Control and Data Acquisition – SCADA- systems are possibly the fastest advancing areas of the various industries today (Water, Oil & GAS, Sewage, etc.). Here at Thrust Automation are at the forefront of controls and automation technology. We have the capability to incorporate the latest PLC and SCADA technology into any of our control panels.

Our SCADA systems are configured to the customers’ requirements by our own staff and range from simple Human-Machine Interfaces to complete monitoring and control systems.

Supervisory Control and Data Acquisition – SCADA- systems are possibly the fastest advancing areas of the various industries today (Water, Oil & GAS, Sewage, etc.). Here at Thrust Automation are at the forefront of controls and automation technology. We have the capability to incorporate the latest PLC and SCADA technology into any of our control panels.

Control systems in the process and manufacturing industries can range from simple sequential logic controllers with few inputs and outputs to complex systems with thousands of I/O’s, complex control algorithms and time critical performance requirements.

Most industrial control applications can be readily managed by Programmable Controllers. The fast leaps in CPU performance and enhancements of programming utilities, eliminates the need for DCS and more traditional proprietary approaches to automation solutions

Control systems in the process and manufacturing industries can range from simple sequential logic controllers with few inputs and outputs to complex systems with thousands of I/O’s, complex control algorithms and time critical performance requirements.

Most industrial control applications can be readily managed by Programmable Controllers. The fast leaps in CPU performance and enhancements of programming utilities, eliminates the need for DCS and more traditional proprietary approaches to automation solutions